Application of ultrasonic cleaning machine in cleaning solar cells

Browse Volume:1151 Classify:Support

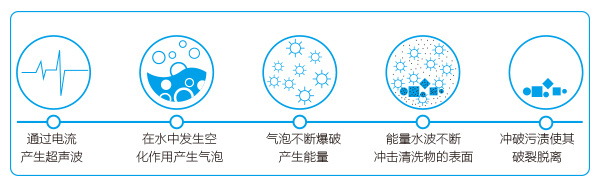

The cleaning technology of ultrasonic cleaning machine is diversified. The common cleaning technologies include multi frequency cleaning, ultrasonic vibration cleaning, focusing cleaning, MHz cleaning and cavitation effect cleaning. Among them, cavitation effect cleaning is widely used. Through the vibration of ultrasonic wave on the cleaning liquid, micro bubble cavitation is generated to act on the cleaned object, so as to realize rapid cleaning.

The solar cell manufacturer uses the cleaning principle of ultrasonic cleaning equipment to clean the battery:

In the process of solar cell printing, there will be many defective products. And the printing materials need to be cleaned and reworked. Because the ultrasonic cleaning machine does not need to be in direct contact with the cleaned object, and the damage to the object is very small during the cleaning process. It is used by the battery factory to clean defective battery chips. The traditional method for treating defective cells is to manually scrub them with terpineol on a lint free cloth, but this method is not only difficult to remove the slurry on the cells, but also easy to damage the antireflection film on the surface, resulting in battery leakage or low battery conversion efficiency.

The ultrasonic cleaning machine makes use of the cavitation, acceleration and direct current effects of ultrasonic wave in the liquid to directly or indirectly act on the dirt of liquid and battery chip, so as to disperse, emulsify and peel off the dirt layer, so as to achieve the purpose of cleaning.

Cleaning principle of ultrasonic cleaning machine

Solar cell manufacturers choose high-power ultrasonic cleaning machine. Which can complete more than 20000 interactive high-frequency transformations of pressure reduction and compression force in one second. In the process of equipment decompression, vacuum nuclear bubbles appear in the liquid. When the compression force is applied, the vacuum nuclear bubbles are under pressure. When they are crushed, a strong impact force will be generated, which will only cause the battery slurry to fall off and will not affect other substances such as antireflection film.

Granbo Sonic

Granbo Sonic

Hello!